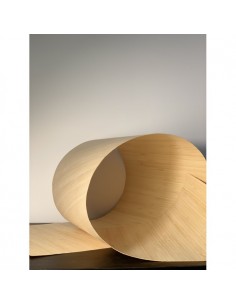

Thin Air Press Kit 20x70"The Thin Air Press Kit 20x70 is designed for laminating custom skateboards using our uncut veneer sheets, including our uncut skateboard molds. It can also be used to for woodworking projects such as archery bows, furniture parts, paddles, etc. The kit can be re-used many times, and with a little care and maintenance, can last for hundreds of pressings.

|

FAQIs this reusable, and for how many times? The kits are designed to be used many many times. With a little care and maintenance, the TAP Kits will last for years. Will the glue stick to the bag? One board at a time. You are limited by how fast your glue dries. Once you start spreading water-based glue on the veneer sheets, you have about 7 minutes to get them pressed before the glue dries. Dry glue will not bond together. How can I get the air out faster? These larger bags have a lot of air in them at the start. A quick way to remove most of the air is to remove the top cap of the grey valve and hover a vacuum hose over the valve. Much of the air can be removed however vacuum cleaners are high volume but low pressure so they will not generate the pressure required to press a deck. Quickly reattach the cap onto the valve and finish the high pressure pumping using the Super Pump. Why not use an electric pump system? Because this is easier! The TAP valves are designed to work with the manual pumps supplied. The beauty of these one-way valves is that the pump does not need to be hooked up for the entire time the project is drying in the bag. The bag remains air tight, so that you dont need a constantly running pump. Once a project is pressed, it can be set aside while you go onto other pressings. If the TAP Bag gets a hole in it, can I fix it? Do the valves leak? While many people assume air is leaking back through the valve, they are made of cast rubber and almost never leak. The most common problem with slow leakage is the open-end seal tape. If the seal is not properly closed up (check both sides) you will lose vacuum. If the top cap of the valve is not compromised with dust and debris, the valve will not leak. Do you refund my veneer if the pressing doesn't work? Sorry, we don't offer reimbursement for these types of problems. It means to press your project in the TAP bag, without putting any glue on the veneer sheets. Stack the dry sheets of veneer over the mold, seal them into the press with the breather netting in place, and pump the air out. Check for 10 minutes to make sure the TAP bag is not leaking. This will help you become familiar with the process before you commit glue to your veneer sheets. |

Thin Air Press Kit 20 x 70"

In Stock

€129.00

Tax included

A simple and effective way to press custom boards and woodworking projects.

Description

Product Details

Reviews

No reviews

Customer reviews

Reviews about this product

-

For my purposes good and cheap (Translated review)

-

This is such a clever way to press irregular shapes together. Just pump the air off and wait for the glue to dry. Simple, easy and no heavy machinery needed!

-

Nothing to say first use perfect. Very strong pocket (Translated review)

Customers who bought this product also bought:

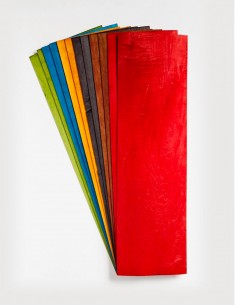

€6.00

2 rolls of sealing tape. Use this to replace worn out tape after your original seal and replacements are used up.

€6.00

Natural coloured 0.5 mm thick bamboo veneer, cross grain.

€3.44

Maple veneer scrap sheets for recycling into new projects.

€72.00

Created for making very long dancing boards, snow, surf, ski and powder boards.

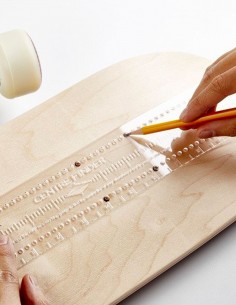

€41.00

Ideal for finding and marking your truck holes.

€70.00

A simple and effective way to press pre-shaped veneer sets.